Chemical Resistant Conveyor Belt Supplier, Manufacturer in Mumbai.

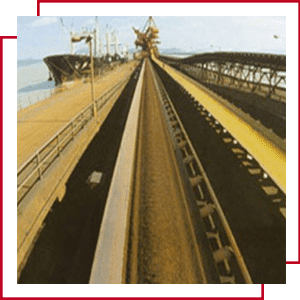

Chemical Conveyor Belt

Our state of the art construction facility has allowed us to fabricate extensive range of conveyor belt to cover entire industrial applications. We have specifically developed a Chemical conveyor belt using varied construction materials. For both the interior carcass and the outer cover, we use only the highest quality materials.

We use Nylon, Urethane, polyester, Lether, and other materials as per requirement. Our oil-resistant series of chemical conveyor belts are suitable for bulk conveying with a predefined rate. It was energy-efficient because of the best lubrication mechanism. It works with low friction. Our offered range of conveyor belts is fabricated on the basis of our research work.

- Chemical Conveyor Belt Exporters

- Chemical Conveyor Belt Suppliers

- Chemical Resistant Conveyor Belt supplier

- Chevron Conveyor Belt Supplier

- General Purpose Conveyor Belts India

- Chemical Conveyor Belt India

- Chemical Conveyor Belt Manufacturers

- Chemical Resistant Conveyor Belt India

- General Purpose Conveyor Belts Exporter