World’s Most Trusted Conveyor Belt Manufacturers, Exporters & Distributors

As leading suppliers of high-performance conveyor belts, we provide custom solutions from modular plastic to heat-resistant rubber that outperform standard factory specs.

Shetty Enterprise is a renowned Conveyor Belt Manufacturer, Exporter, and Supplier in India since 1999 and has over 25 years of experience in the industry, good performance and reliability in offering solutions involving conveyor belts to different markets around the globe.

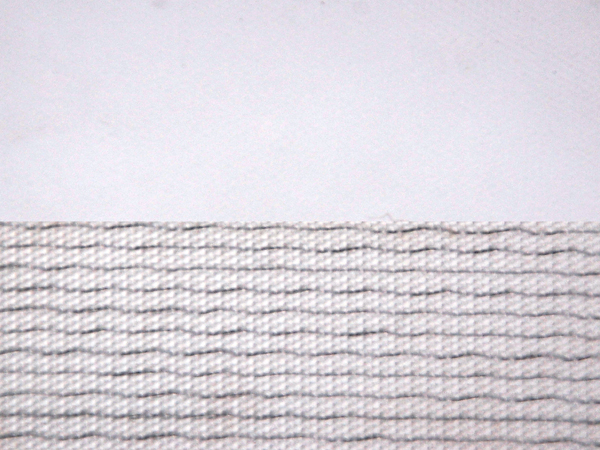

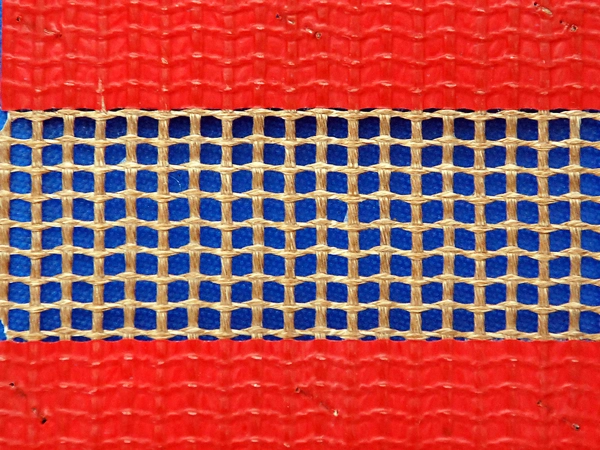

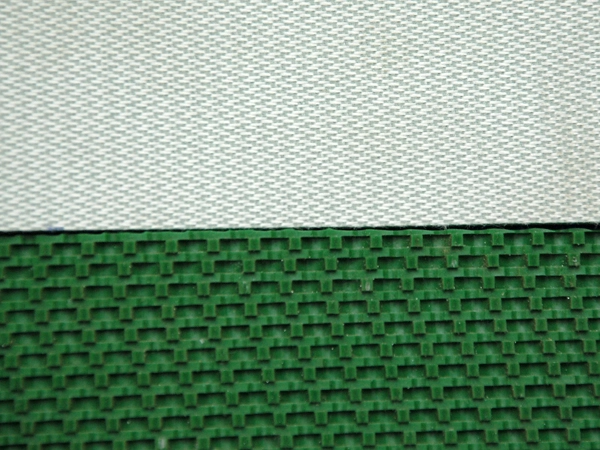

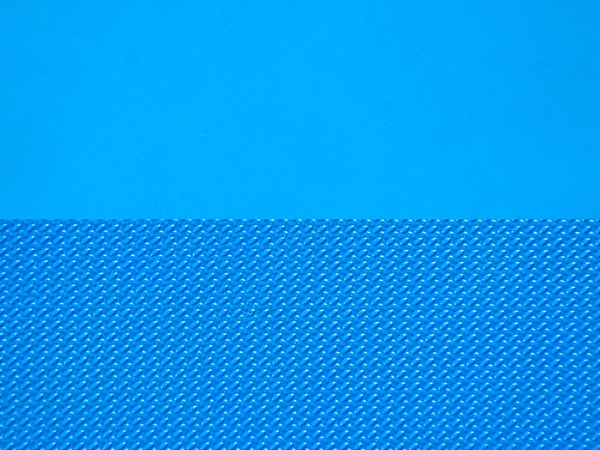

Being one of the reliable conveyor belts manufacturers, the company proposes an enormous diversity of such products as rubber conveyor belts, heat-resistant conveyor belts, chevron conveyor belts, heavy-duty conveyor belts, food conveyor belts, PU and PVC conveyor belts, and even fully customized material handling systems that will be coordinated to operate together with the processes in an industry.

Shetty Enterprise serves major industries in mining, cement, steel, packaging, food processing, and logistics with high production and quality-control capacity, application-specific design and expertise. Durability, innovation, and delivery on time guarantee the company maximum efficiency and service life of all the conveyor belts provided to its customers in India and across the world.

Our Products Range

Shetty Enterprises is a reputable Manufacturer, Exporter and Supplier of the Conveyor Belt, Food Conveyor Belt, Tea Leaf Conveyor Belt, Potato Conveyor Belt, Meat Conveyor Belt, Textile conveyor Belt that are being produced using the high quality raw materials, and produced in the international standards.

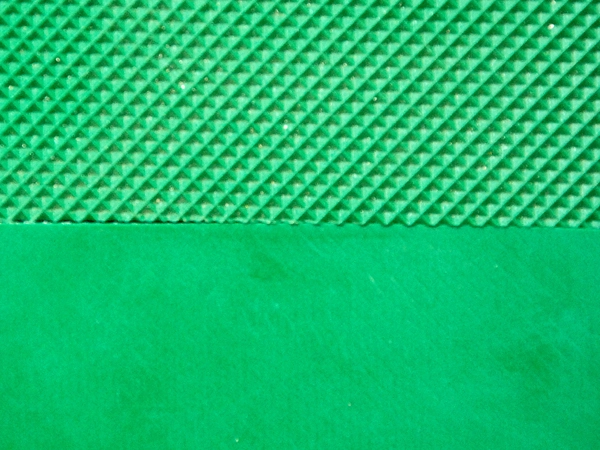

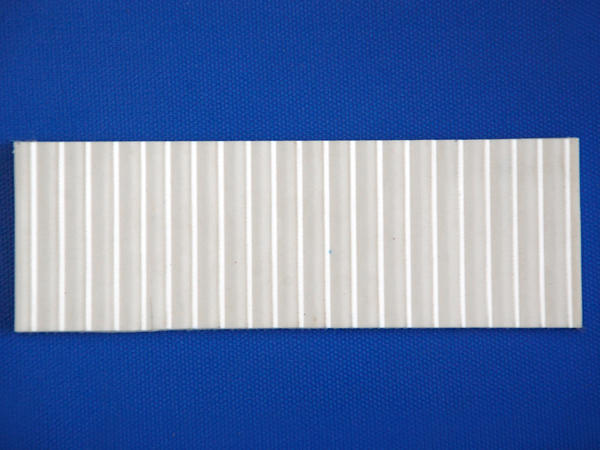

Discover superior material handling with India’s number one Cleated Conveyor Belt Manufacturer, Exporter & Supplier. Our cleated conveyor belts are designed to provide precise and efficient transportation, preventing rollback across a wide range of industries, from agriculture to manufacturing and everything in between.

Maximize your process with incline transporting to minimize material wasted to slip using our high-performance, durable and reliable solutions designed with operational efficiency and maximum productivity in India and beyond.

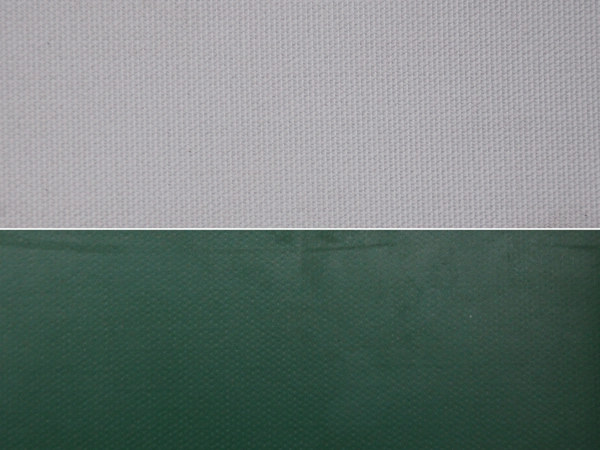

We are the top Meat Conveyor Belt Manufacturer, Exporter, and Supplier of hygienic, FDA-compliant belting solutions that are functional in the meat industry located in India. Our meat conveyor belts can resist the oils and fats present in meat and can be cleaned and sanitised easily to stop cross-contamination. Our conveyor belts enable you to process meat safely and in less time, so that your activity becomes highly efficient in India and the global markets.

We are a leading Metal Detector Conveyor Belt Manufacturer, Exporter and Supplier of high-end inspection solutions in India. Our systems can recognize ferrous, non-ferrous, and stainless steel contaminants with accuracy to ensure the quality of your product and the accuracy of your equipment. Our belts can be applied to industries with high demand, like food and pharma. The high-sensitivity belts help you to make sure that you are complying with strict quality control and enforcement of compliance in your production facility around the world.